Cutting discs are an exciting part of the wonderful world of embarking on a journey much like walking into an Aladdin’s cave, full of treasure, each one glistening with possibility and purpose. These tools are not only helpful in cutting and grinding, but they are indeed the unsung heroes of most workshops, construction sites, and manufacturing plants across the globe. Let’s get into the thick of the cutting disc world and become aware of the type of cutting disc, the diversity of materials it is made from, and the many applications it handles very well.

Cutting discs are an exciting part of the wonderful world of embarking on a journey much like walking into an Aladdin’s cave, full of treasure, each one glistening with possibility and purpose. These tools are not only helpful in cutting and grinding, but they are indeed the unsung heroes of most workshops, construction sites, and manufacturing plants across the globe. Let’s get into the thick of the cutting disc world and become aware of the type of cutting disc, the diversity of materials it is made from, and the many applications it handles very well.

The Pantheon of Types

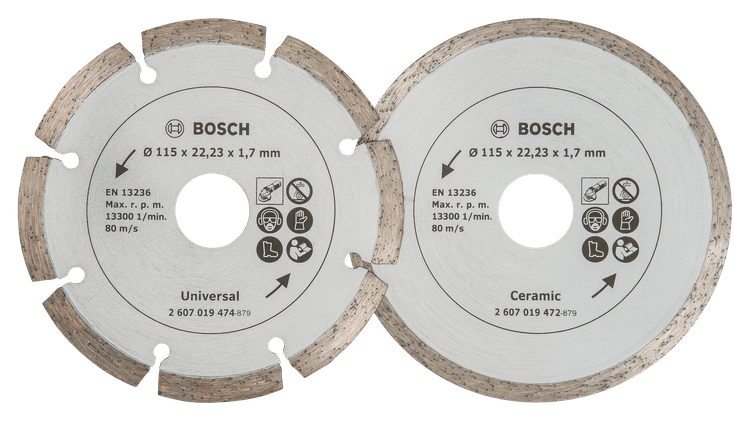

Not all gladiators are made equal in the grand coliseum of cutting tasks. Every type of cutting disc is sharpened to contend with the exacting material that holds unique properties, making it the champion in its arena. Abrasive discs, somewhat resembling the tools of a veteran swordsman, are the traditional thing for cutting metal. With sparks flying in their wake like fireworks, of course. On the other flank are diamond-tipped disks—elite knights with armory-piercing capability and the fancifulness of a ballet dancer, able to cut through the hardest materials.

Crafting the Blades: The Alchemy Behind Materials

So, creating cutting discs was almost alchemy: the right elements mixed together would conjure a tool full of great power. And aluminum oxide was the perfect mix, ever prepared to serve ferrous metals. Silicon carbide, rogue of the group, excelling with non-ferrous metals and masonry, its sharpness unforgiving. Then there is the noble diamond, crown-jewel tough to the point of being unrivaled. Its ability in cutting concrete and tile is to that of butter left outside on a sunny day.

Applications: The Quests They Undertake

Cutting discs are not tools; they are adventurers on their respective journeys through realms of metal, stone, and anything that may lie in-between. In the automotive industry, the discs are the surgeons cutting through metal for repair and well, creation. In the construction, it is the world that they lay, slicing through materials to build the edifice of our everyday lives. In do-it-yourself activities, these make for the best companions helping hobbyists bring their visions to life with flair and precision. Safety: The Shield Against the Perils But adventuring with this cutting disc is never without perils; safety becomes the shield that every wielder must bear. Know which one is the right disc for the right job. It’s not wisdom; it’s a chant for safety. And the protective gear donned in this story is knight’s armor against the sparks and junk waltzing like dragon fire.

Innovation: Gazing Into the Crystal Ball

Standing on the edge of the future, the development of the cutting disk tells but a few chapters. It continued to evolve the material it is made from, and today some of the most promising technologies include disks embedded with nanodiamonds or made of sustainable material. It’s a horizon ripe with potential, where cutting discs not only shape materials but also the future of industries.

Conclusion

Thus concludes our odyssey through the world of cutting discs. From the great diversity in types and materials to their immense landscapes of application, these tools become silent warriors of creation and demolition. These are reminders that the heart of every cut, grind, or slice, in actuality, contained not just the transformation of materials, but really, the embodiment of human ingenuity and tireless progress. Regarding the future, with cutting discs, the one thing that is an epic still rolling from the workshops and sites around the world, written in chapters, is this is not the end of the story.